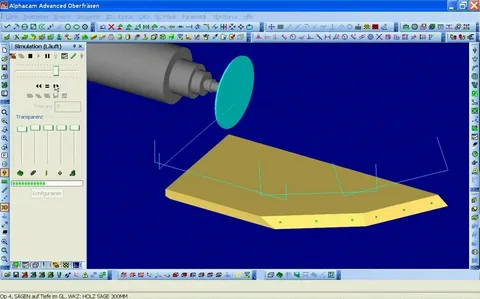

Alphacam software free download full version

Alphacam is a powerful and intuitive CAD/CAM software designed for woodworking, metal cutting, and stone cutting industries. It offers a wide range of functionalities that streamline the manufacturing process, making it a preferred choice for many professionals. Whether you’re dealing with simple routed parts or complex 5-axis components, Alphacam can significantly enhance your CNC machine’s performance.

Modules of Alphacam

Alphacam Core

The core module of Alphacam includes essential functionalities such as CAD importing, toolpath generation, simulation, and report generation. It serves as the foundation for all other modules, providing a comprehensive solution for part programming.

Alphacam xPositional

This module unlocks positional axes for machining on an angle, allowing for more complex and precise machining operations. It’s particularly useful for industries that require high levels of accuracy and detail.

Alphacam xSimultaneous

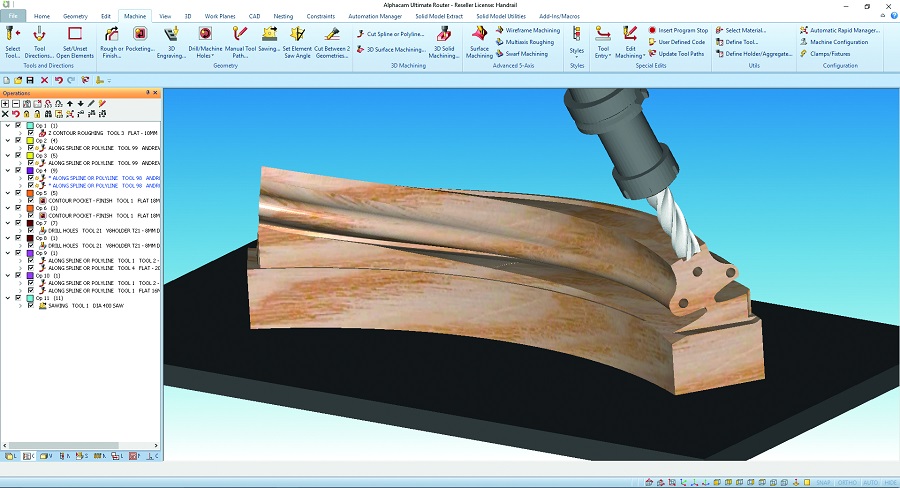

Alphacam xSimultaneous offers support for 5-axis machinery with fully interpolating heads. This module is ideal for advanced machining operations that involve complex geometries and require simultaneous multi-axis movements.

Alphacam xSolids

With Alphacam xSolids, users can process solid models and assemblies, preparing them for manufacturing. This module enhances the software’s capability to handle complex designs and streamline the production process.

Alphacam xNesting

The xNesting module provides industry-leading nesting technology, ensuring productive, optimized, and efficient nesting of parts on a sheet. It includes robust reporting features for part traceability, making it easier to manage and track production.

Alphacam xAutomation

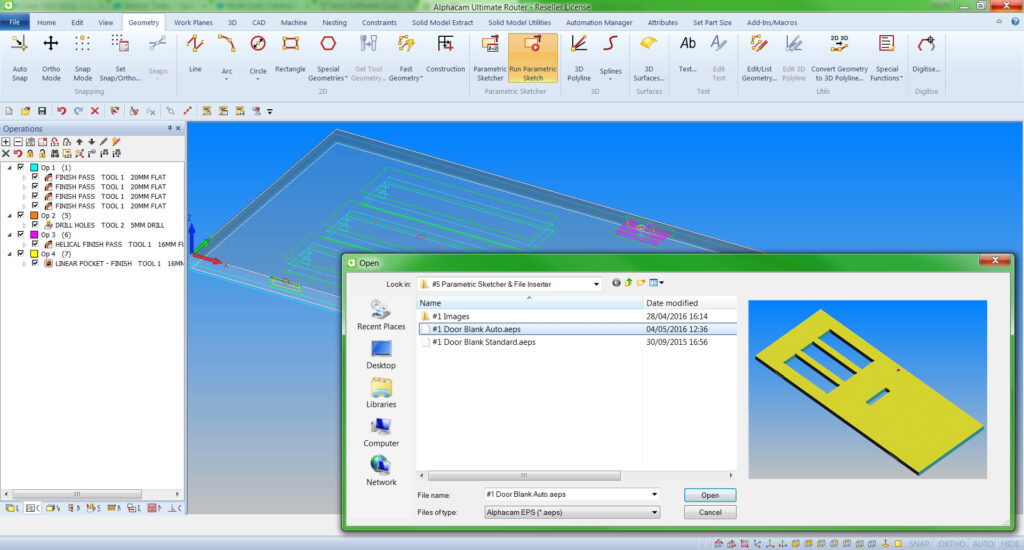

Alphacam xAutomation allows users to batch process 2D and 3D CAD files, along with solid models. This module is designed to automate repetitive tasks, saving time and reducing the potential for errors.

Alphacam xConstraints

This module provides parametric programming for creating smart, constrained parts and geometries. It enables users to define relationships between different elements, ensuring consistent and accurate designs.

Alphacam xFixtures

Alphacam xFixtures gives users full control over the design, placement, and simulation of clamps and fixtures. This module is essential for ensuring that parts are securely held during machining, reducing the risk of errors and improving overall quality.

Alphacam xAPI

The xAPI module enables developers to extend the functionality of Alphacam using standard programming languages. This feature allows for greater customization and integration with other software systems.

Alphacam xRobotics

Alphacam xRobotics provides the ability to output tooling and toolpath data for third-party robotic post-processors. This module is ideal for industries that utilize robotic machining, offering greater flexibility and efficiency.

Benefits of Using Alphacam

Increased Productivity

Alphacam’s automation features and efficient toolpath generation significantly increase productivity. By reducing the time required for programming and setup, users can focus more on actual production, leading to higher output and profitability.

Enhanced Accuracy

The software’s advanced simulation and nesting technologies ensure that parts are machined with high precision and minimal waste. This accuracy translates to better quality products and reduced material costs.

Flexibility and Customization

With its wide range of modules and customization options, Alphacam can be tailored to meet the specific needs of different industries. Whether you’re in woodworking, metal cutting, or stone cutting, Alphacam offers the tools and functionalities required to optimize your manufacturing process.

User-Friendly Interface

Despite its advanced capabilities, Alphacam boasts a user-friendly interface that makes it accessible to both beginners and experienced professionals. The intuitive design and comprehensive documentation ensure that users can quickly get up to speed and start leveraging the software’s full potential.

Features of Alphacam

Alphacam comes equipped with a variety of features that cater to different aspects of design and manufacturing. Some of the key features include:

- User-Friendly Interface: The software is designed with an intuitive interface that simplifies navigation and enhances user experience. This is especially beneficial for new users who may not be familiar with CAD/CAM software.

- Advanced Nesting Capabilities: Alphacam offers powerful nesting tools that optimize material usage and reduce waste. This feature is essential for companies looking to improve their sustainability and cost-effectiveness.

- 3D Modeling: Users can create detailed 3D models, allowing for better visualization and accuracy in manufacturing. This feature is particularly useful for complex designs that require precision.

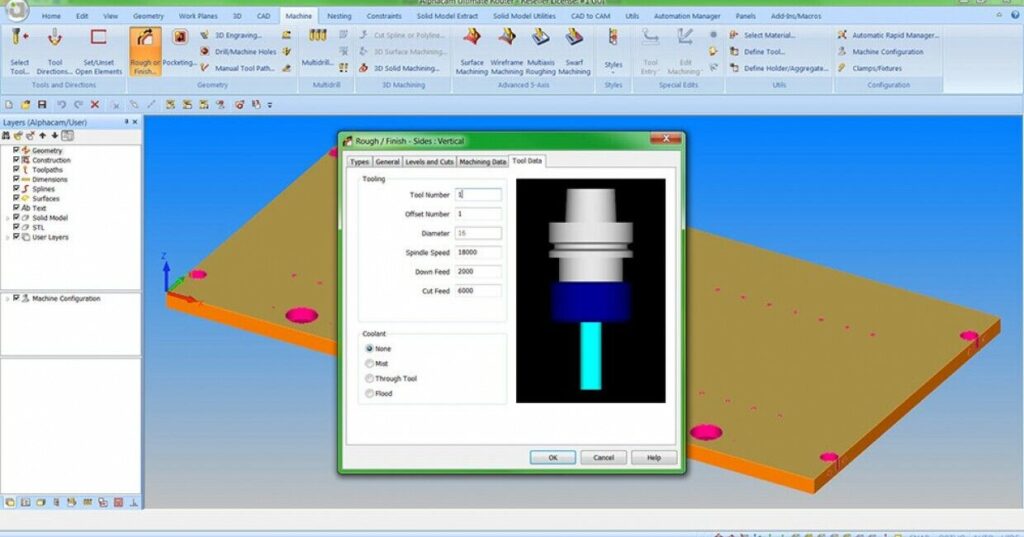

- Toolpath Generation: The software automatically generates toolpaths based on the designs, ensuring efficient machining processes. This automation saves time and minimizes errors during production.

- Post-Processor Support: Alphacam provides a wide range of post-processors for various CNC machines, making it adaptable to different manufacturing environments.

For a deeper dive into these features, you can visit Frezsa and Get Into PC.

Technical Specifications

Before downloading Alphacam, it’s essential to understand its technical specifications:

- Version: Latest Release

- Interface Language: English

- Design By: Alphacam Development Team

- Type of Software: CAD/CAM Software

- Audio Language: N/A

- Uploader / Repacker Group: Official Release

- File Name: alphacam_setup.exe

- Download Size: Approximately 500 MB

System Requirements

To ensure optimal performance, consider the following system requirements:

- Minimum Requirements:

- OS: Windows 10 or later

- Processor: Intel i3 or equivalent

- RAM: 4 GB

- Graphics: DirectX 11 compatible graphics card

- Recommended Requirements:

- OS: Windows 10 or later

- Processor: Intel i5 or equivalent

- RAM: 8 GB

- Graphics: Dedicated graphics card with 2 GB VRAM

How to Download and Install

To download Alphacam, follow these steps:

- Click on the above download button to access the setup file.

- Run the downloaded file and follow the installation prompts.

- Enter the password provided in the download guide to complete the installation.

How to Start Using Alphacam

After successfully installing Alphacam, follow these steps to get started:

- Launch the software from your desktop or start menu.

- Create a new project by selecting “New” from the main menu.

- Import your design files or create new ones using the design tools available.

- Generate toolpaths and prepare your project for CNC machining.

- Save your project and export it to your CNC machine for production.

For further insights and resources, you can visit websites like Ocean of Games and Deffrent. Each site offers unique resources and insights, so feel free to explore them to find the information you need.

Leave a Reply